Marnie Surfaceblow: Even Minor Alarms Can Lead to Major Safety Improvements

Credit to Author: POWER| Date: Mon, 03 Apr 2023 04:09:00 +0000

Long-time POWER readers may remember Marmaduke Surfaceblow, a fictional character whose engineering escapades were brilliantly portrayed in hundreds of stories published within POWER magazine’s pages over more than 30 years beginning in 1948. Today, the fictional series continues through Marmy’s granddaughter, Marnie, who is an engineering wiz in her own right.

When investigating any potential problem, keep your eyes and your mind open to other possible dangers.

“I am starting to wonder if you accepted this assignment because of … that,” stated Maya Sharma, lead field engineer for Surfaceblow & Associates International. She sipped her tea in the reception area of the biomass power station, watching her boss peering intently at a 1:100 scale model of the boiler.

“Incredible! Fantastic! It’s so rare to see these nowadays!” Marnie Surfaceblow, the firm’s vice president, walked around the model, peering through the plastic girders. “Look at the detail on the fourth level turbine deck, Maya! This wee plastic worker has a cute little lunch pail and matching thermos! And it’s in Royal Stewart tartan! Although I don’t think I’d picnic next to the boiler feed pump turbine …”

“Ma’am! Are you listening to me?” Maya emphasized, nonplussed.

“Mmmm hmmm … I assure you this is purely coincidence. I wanted to make a sales call while we were in the Philippines to scare up some new business, and while talking to the plant manager he mentioned this concern about their biomass fuel silos. Wow, this model has everything! I want to take it home with me. I wonder if they’d trade some consulting work for it. You know, in Grandpa Marmaduke’s day, we had an entire modeling shop that would create these for prospective clients on large jobs. It added a certain elegance to the proposal, made it more real,” said Marnie.

“With respect ma’am, your last Prada suit exhausted your petty cash, so no more souvenirs—please. This power station has a carbon monoxide problem, and you know how I feel about poisonous gases,” Maya added while crossing her arms and giving her boss “The Look.”

“Fine,” muttered Marnie, “probably couldn’t get it through customs anyhow. Do you think they would let me …”

“No, ma’am. Kindly return the plastic plant engineer and their lunch accessories to the assigned position by the turbine,” directed Maya.

Problems with a New Fuel

Luis Phillipe Santos had been the plant manager for the last two years, and it was clear that he was concerned—as were his team of engineers and operators gathered in a spacious conference room separated from the control room by a large glass wall. “It was very good that you called me and even better that you were here in our country, Señora Surfaceblow,” the plant manager began. “We have doubts about our biomass silos and believe we are facing complete disaster, so we are not able to operate.”

“Let’s go step by step through the issues,” Marnie replied. “This was a small lignite coal plant that was built sometime during the Nixon administration and shut down six years ago. Your company purchased the plant three years ago, and decided that since the mills had enough capacity to grind the glorified dirt you were burning before, you could retrofit them to burn biomass pellets. You have retrofitted all four mills, and added 50,000 tonnes of sealed storage to protect it from the elements—thank goodness—and last year you did a successful test burn with white wood pellets. Since then, you’ve been burning biomass for …” Marnie paused as she flipped through her notes, while Maya assisted by answering, “123 days.”

Luis Phillipe nodded agreement. “Yes, very exact. However, we did make one small change. After commissioning was complete, we changed the fuel source to white agricultural waste pellets—maize cobs and stalks,” he said.

“With respect sir, that is not a small change,” Maya interjected.

“Yes, well, to be profitable we must adapt,” Luis Phillipe responded. “But now we have doubts about the new pellets; I will have my team explain. Miguel?”

|

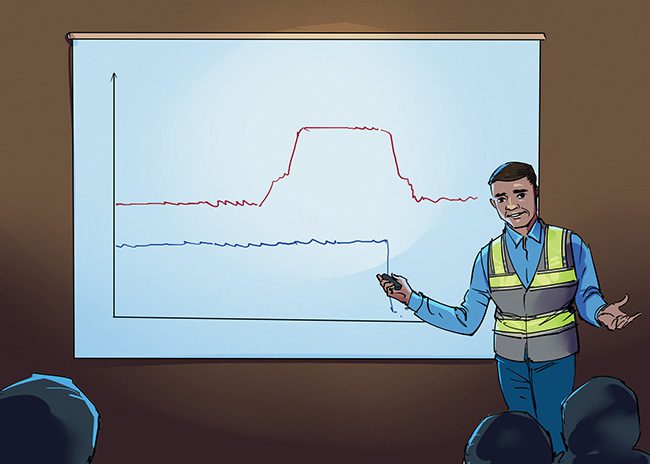

1. Miguel presents data showing unusual hot spots occurring from time to time in the bottom of the fuel storage silos. Source: POWER |

A young man, who introduced himself as lead operator Miguel Flores, took the floor and turned on a large display showing multicolored plant data trends (Figure 1). “Our remote monitoring engineers in India alerted us of this, and we confirmed it with hand measurements. In the bottom of the fuel silos, we are seeing temperature increases that come and go. They started less than a week after we loaded the silos with pellets. They are hot spots from self-heating or combustion in the bottom of the silos. You see here, suddenly these two silos that were measured at 25 to 28 Celsius rise to nearly 50C, then return to normal after we shut the mills down.”

“We are very cautious of this as we encountered five mill fires from excess fuel accumulation in the mills,” interjected Valentina Diego, the plant mill maintenance expert. “We greatly increased the air flow and modified the classifiers, so the pressure drop across the mills is much higher and the pulverized fuel is now flowing. However, we are afraid these hot spots in the silos will lead to disaster.”

“As well you should be,” Marnie sternly replied. “Mill fires lead to not only damaged equipment, but the potential for an explosion, which could very easily be fatal.”

Valentina nodded her head. “Indeed, we have had one small pressure spike from combustion …”

“I just heard ‘explosion,’ not ‘pressure spike,’ ” Marnie interrupted.

“OK, then, expert lady, explosion from fuel deposits in a fuel pipe,” Valentina scowled.

Luis Phillipe stepped in, “Let us tell our guests about the CO measurements.” Marnie noticed Maya immediately tensing, her full attention riveted on a wizened plant engineer. Looking as if he carried more years of plant experience than the rest of the room combined, a gentleman introduced with reverence as Señor Franco shakily stood up, and with the help of Miguel called up another screen onto the display.

“I always have doubts about this new fuel, so I walk the power station and monitor gases—explosive, poison, suffocating. I walk the station and always watch,” the seasoned plant veteran explained. “So, this week I walk the floor over the silos, and I find CO. And, I put monitors over each silo.” Señor Franco paused, while Miguel typed a few buttons and highlighted CO reading trends.

“Sir, I admire very much your dedication to safety. These CO measurements are very low, one to eight parts per million, and mostly under five. Is there not always some CO near the fuel handling system?” Maya asked.

Señor Franco shrugged, “Never have I seen any CO above the fuel silos. It is small, but my instruments are calibrated daily.”

“That … does warrant notice, sir,” agreed Maya. “I wish to examine all historical data since operation on biomass began.”

“And I want to examine the fuel silos and the mills,” added Marnie. “Maya, can I borrow your collection of gas sensors?”

Silo Operation and CO Monitoring

The plant was dark and relatively quiet, save for occasional distant clangs and conversation as the staff took advantage of the unplanned outage to perform some repairs and preventive maintenance activities. Marnie, Señor Franco, Miguel, and Valentina gathered around the steel grating covering the fuel silos. After tying off for safety, Marnie leaned over to peer through the grating on top of the silos, but her flashlight couldn’t penetrate the lingering biomass dust cloud. Not to be defeated, she produced her high-powered hand-held green laser and shone it down through the dust to gauge the height of the fuel pile in each silo. After a moment’s observation, she asked, “Why are silos one and four nearly full of fuel, but silos two and three are less than half full?”

“We have raised the plant capacity with pellets step by step, starting with the middle two mills. We were going to start three-mill operation soon, but then, well, the CO,” Miguel said. Then turning to Señor Franco, he asked, “Señor, where was the CO most concentrated?”

Señor Franco pointed to the number two and three silos, and replied, “Mostly these, but a trace in the others. It drifts, as you know.”

“And when did you install the permanent CO monitors?” asked Marnie.

Miguel checked his notes and replied, “Last month. We didn’t notice the CO in the control room because it was under the alarm point for worker safety, but not for impending or slow combustion. We have since corrected that error and are grateful Señor Franco checked this himself.”

“Look, I know every safety agency has exposure limit curves, but really now, CO is like mercury—there is no lower limit that is truly safe. And if it implies a fire, then we have a serious problem. Where are your temperature sensors on the silos?” Marnie asked.

Miguel pointed to one sensor mounted in the grating and replied, “Also there is one sensor every three meters until above the bottom cone, there we have four sensors.”

“Why at the bottom of the silo? Why not near the top? The heat would rise to the top,” Marnie said.

Miguel and Señor Franco shrugged. Valentina offered, “I believe we thought that would be the wettest area and prone to more heating from the moisture.”

“I see,” said Marnie. “I noticed water standing up here. Your roof is in terrible condition, and here, right here,” she highlighted a tiny rivulet wending from the wall, “it’s leaking into silo number two right now!”

Valentina and Miguel both sighed. Miguel responded, “We have spent much on roof repairs, but our budget is continually reduced. We do what we can, but …”

“I know, but you also know this isn’t good. Let’s examine the feeders and mills,” Marnie said, leading the way and shaking her head.

Feeders and Mills

The number two and three feeders and mills were currently open for inspection, and it was clear there was water actively draining in a slow drip from the bottom of the silo cone. “How does your biomass even flow when it’s that wet?” Marnie asked.

“We have pluggage at first, and then it will start to flow. Señor Franco says we should redesign the bottom cone to be, I think, a hyperbola? But we have not the time, and we have the hot biomass and CO to be concerned about,” answered Miguel.

“You only have a small amount of spilled biomass, but some of it looks slightly charred.” Marnie frowned to herself, and then took her thermal camera from her latest Prada purse and started scanning the area. “I’m not seeing much in the way of heat right now. And the CO readings were low, despite the wet fuel that should be self-heating. So, why … let’s examine the mills,” she said.

|

2. Marnie and Señor Franco inspect a mill. Source: POWER |

Descending to the next level where the mills sat open for inspection as well, Marnie examined each in turn as much as possible without requiring site confined space certification (Figure 2). “There’s some sign of wet fuel buildup here, and in the pulverized fuel pipes, and the downspout, and … everywhere,” she noted.

“Señora,” said Señor Franco quietly, “often the reject spouts are blocked when the fuel is wet, and sometimes the pulverized fuel pipes. I have doubts, as the mill pressures are very high, yet fuel will not flow. I wonder. Does the hot air go where it should not?”

Marnie smiled at Señor Franco, and took the elderly engineer’s hands in hers. “Indeed, my wise friend, exactly what I was thinking.” Marnie then fumbled for her phone and called Maya.

“Maya! Have you been looking at the control system data trends of mill operation versus the CO measurements?” she asked.

A long silence followed. “Yes, and I believe I have an idea as to the problem,” Maya responded. “Can you please inspect the connections from the silo to the feeder, and from the feeder to the mills, and see if there is evidence of biomass fuel deposits that are, how you say, baked on?”

“Give me a few minutes,” said Marnie. With the help of Señor Franco, Marnie was able to look up the fuel feed pipe to the feeder, and then the two walked back up a level to examine the connection between the feeder and the silo. They looked at each other and nodded. Marnie phoned Maya back. “Yes, the deposits are present in both areas, but much worse at the mill—practically carbonized in fact,” Marnie reported.

“Very good ma’am, we should call a meeting and discuss many things,” replied Maya.

“Oh, like in the Lewis Carroll poem: ‘Of biomass and water, running all around, and why the silo cone is warm, and CO sometimes found?’ ” Marnie retorted.

A long silence followed. “Ma’am, is your personal CO monitor working properly?” Maya asked, only partially kidding.

Relatively Simple Solutions

“So,” started Marnie, as the meeting room discussions quieted down. “I have some good news, some bad news, and some terrible news. Which first?”

Miguel sighed, “The terrible news, please.”

“Right!” Marnie exclaimed. “The terrible news is there is no coffee. Why is there no coffee? I don’t want to live in a world without coffee …”

“Ma’am!” interrupted Maya, who held out a steaming cup of what appeared to be bunker fuel oil mixed with milk, that is, power plant coffee.

“Thank you, my able assistant. Why don’t you start with what you found from your data analysis, while I try to replace my blood with this,” said Marnie.

Maya stood and surveyed the audience. “In my country, many believe water carries energy. Water moves energy, water can give energy, and it can take energy,” she began.

“That explains why coffee is so powerful,” muttered Marnie. Maya ignored her and pressed on.

“My auntie Deepika believes such, and in this case the problem is water is taking energy from the mills by increasing the air pressure drop moving the pulverized biomass.” Maya flipped to a screen of plant data trends over several months. “See here, every occasion your biomass fuel is wet, you must increase mill air flow to dangerous levels. At 40% feeder speed, you require nearly full primary air flow. With coal, your mill operating pressure was no greater than 18 mbar. Now you routinely operate at 26 to 30 mbar, and when the fuel is quite wet, the pressure increases to 36 mbar. This has many unintended consequences,” Maya said.

Bolstered by her coffee, Marnie stood up and took over, “In addition, you know that every step of the way the water is going to not only turn the biomass into a sticky paste, but it’s also going to encourage self-heating and hot spots as it wets the biomass fuel—and then, if you’re really unlucky, you have combustion and worse. So, pretty please with sugar on it, fix the roof, or at least arrange sandbags around the top of the silos, or something for goodness sake to reduce water leaks into the silo.”

Taking a sip of coffee, she continued. “Up to now, you’ve been lucky and the water isn’t reacting with your current maize-based pellets. But every biomass fuel is different, and you could easily find that the next time you change the fuel, you end up with a much hotter problem,” Marnie said.

Luis Phillipe leaned back in his chair and crossed his arms tightly. “This all may be so, Señora Surfaceblow and Señora Sharma, but why are we detecting heat in the silos, and why did Señor Franco find the CO above the silos?”

Maya flipped to a slide that trended the online CO monitor levels, the silo temperatures, and mill operation parameters, and she then highlighted two trends. “Note here please—both the CO levels and the silo temperatures increase only when the number two and three mills are brought online, and the trend follows the load, or more precisely, the differential pressure across the mills. And when the biomass is wetter and your primary air flow is very high and the pressure drop high, then I believe you are seeing backflow of hot air up into the feeder from the mills, and to a lesser extent into the silos,” Maya speculated.

It was Marnie’s turn, and she flipped to some slides showing digital camera photos from her inspections. “I noted that there were charred biomass pellets spilled around the feeders, and that the down-pipe from the feeder to the mills shows signs of overheating. Even the pipe to the silo has some carbon deposits on it. So, in this case, the fuel is being overheated and there is some slow cooking, but it’s coming from below, not from above. This was further backed by another observation Señor Franco made—that when the biomass is wet, the rejects chutes from the mills are clogged, and this contributes further to high mill pressures,” said Marnie.

Señor Franco shrugged, “I notice things. Always, you must keep your eyes open to changes.”

“Indeed, you must,” agreed Marnie. “In this case, I think the solutions are simple: keep the biomass as dry as possible, monitor your mill pressures more closely, and see about performing maintenance on or upgrading your feeders to provide much better hot air isolation along the fuel flow path. This is something we can help you with.”

A Teachable Moment

After two long days of planning and brainstorming solutions, followed by grateful farewells, Marnie and Maya walked to their rental car accompanied by Señor Franco. As they walked, the wise old engineer said, “Señora Surfaceblow, I almost forgot to mention that I worked with your grandfather on the original plant commissioning. You and he are very different, but I see that you carry in your bloodline an ability to see the details—you seek wisdom, and you know when you discover it. I am happy to have met you and Señora Sharma, and perhaps you both have given me energy to continue working for just a few more years.” Señor Franco shrugged, “After all, it is said that to teach is to live on in the work of those who learn.”

After they said farewell at the rental car, both women sat silently in the car, thinking. Marnie broke the silence by asking, “Do you think it’s possible, Maya, that we live on through teaching?”

“No,” replied Maya, “it is not merely possible, it is the truth.”

—Una Nowling, PE is an adjunct professor of mechanical engineering at the University of Missouri-Kansas City.

The post Marnie Surfaceblow: Even Minor Alarms Can Lead to Major Safety Improvements appeared first on POWER Magazine.